Accessibility is no longer just a design option- it’s a critical requirement in modern infrastructure. Whether it’s a busy railway station, a commercial complex, or a public sidewalk, every space must be safe and inclusive for people of all abilities. One of the most effective ways to achieve this is through tactile indicators, specialized ground surface solutions such as studs, strips, and tiles that provide essential guidance for visually impaired pedestrians.

Among the many tactile solutions available today, PU tactile tiles (polyurethane tactile tiles) have emerged as a durable, versatile, and cost-effective choice. Designed with raised patterns such as warning studs or directional bars, these tiles provide both tactile and visual cues to enhance safety and mobility in public and private spaces. Unlike traditional materials such as concrete or ceramic, PU (polyurethane) offers flexibility, UV resistance, slip-resistance, and easy installation, making it ideal for both indoor and outdoor use.

What Are PU Tactile Tiles?

PU tactile tiles, also known as polyurethane tactile tiles, are specially designed tactile paving products that provide guidance, orientation, and safety for pedestrians, especially those with visual impairments. These tiles are part of the Tactile Ground Surface Indicators (TGSI) system, which is an essential accessibility solution in modern urban and commercial infrastructure.

Made from polyurethane (PU), these tiles combine flexibility, strength, and resistance to environmental wear, making them suitable for both indoor and outdoor applications. They feature raised surface patterns, either warning studs or directional strips, that can be detected by foot or with a cane, ensuring safe navigation in public spaces such as railway stations, airports, shopping malls, sidewalks, and corporate parks.

Types of PU Tactile Tiles

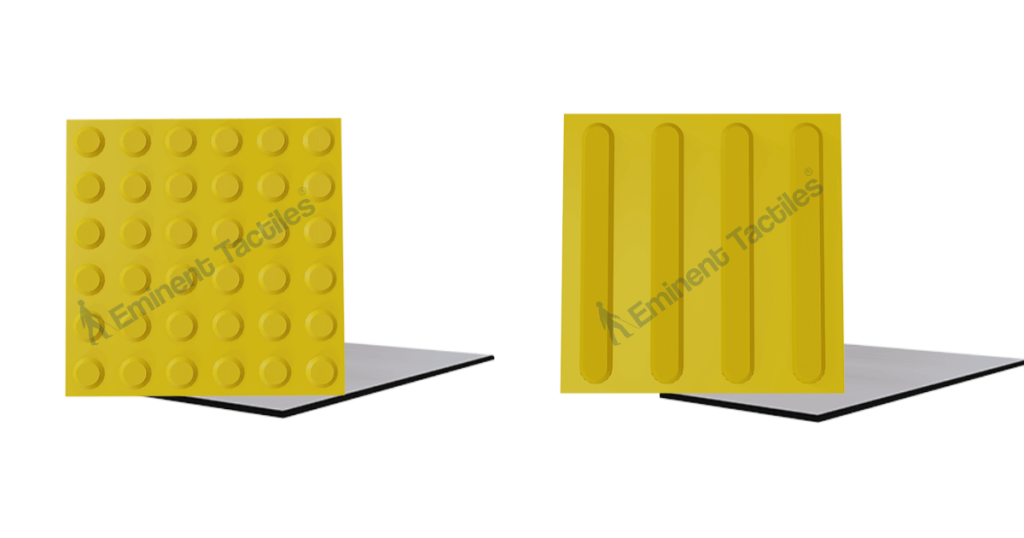

PU tactile tiles come in two primary functional types, each serving a specific purpose in accessibility design:

- Warning PU Tactile Tiles (with Studs)

- Features raised dome-shaped studs.

- Warn pedestrians of potential hazards such as platform edges, staircases, escalators, or pedestrian crossings.

- Provide a clear “stop” or “caution” signal.

- Directional PU Tactile Tiles (with Bars/Strips)

- Designed with parallel raised bars.

- Guide pedestrians safely along a continuous pathway.

- Often installed in transport hubs, shopping complexes, and public walkways.

Why Polyurethane? (Material Advantages)

When it comes to tactile ground surface indicators (TGSI), the choice of material plays a critical role in determining durability, safety, and compliance. Among all available options, polyurethane tactile indicators (PU TGSI) stand out as one of the most durable tactile solutions for modern infrastructure projects.

1. Flexibility and Durability Compared to Ceramic or Concrete

Traditional tactile tiles made of ceramic or concrete often crack under heavy loads, extreme temperatures, or long-term foot traffic. In contrast, PU tactile tiles are highly flexible, allowing them to withstand stress without breaking. This flexibility ensures long-lasting performance in high-use environments such as railway stations, bus terminals, airports, and shopping centres.

2. Resistant to UV, Corrosion, and Weather Changes

Outdoor installations are constantly exposed to sunlight, rain, and temperature variations. Polyurethane tactile indicators offer long-lasting performance, remaining UV-stable and corrosion-resistant, unlike concrete or painted surfaces that tend to fade and wear out over time. They maintain their colour, texture, and grip even in Australia’s harsh weather or coastal environments, reducing maintenance costs significantly.

3. Lightweight Yet Strong

Despite being lightweight, polyurethane is remarkably strong. This unique balance makes PU TGSI tiles easier to transport and install while still handling heavy pedestrian traffic. For contractors, this means faster project timelines and reduced labour costs, without compromising on quality or safety.

4. Slip-Resistant and Safe for High Foot Traffic Areas

Safety is the primary function of any tactile solution. PU tactile tiles are designed with slip-resistant surfaces that remain effective even in wet or oily conditions. This makes them ideal for areas with high foot traffic, including shopping centres, healthcare facilities, universities, and transport hubs. By reducing the risk of slips and falls, PU indicators play a direct role in enhancing pedestrian safety.

5. Eco-Friendly Manufacturing Options

Sustainability is emerging as a central pillar of urban development. Many polyurethane tactile products are now manufactured using eco-friendly processes, with options for recycled or recyclable materials. This makes them an excellent choice for projects aligned with green building certifications or smart city initiatives, where accessibility and environmental responsibility go hand in hand.

Where Are PU Tactile Tiles Used?

The effectiveness of PU tactile tiles lies not only in their durability but also in their versatile applications across indoor and outdoor environments. As part of essential accessibility flooring tiles, they help create safer, more inclusive spaces for pedestrians—especially those with vision impairments.

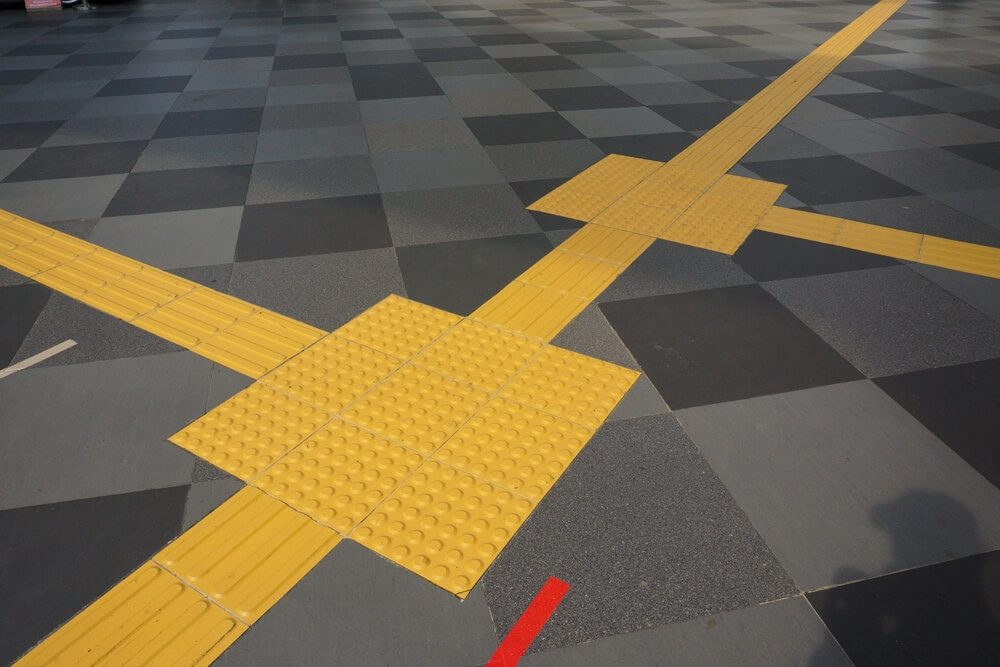

1. Public Transport Hubs

Railway stations, bus stops, and metro stations are some of the busiest public spaces where tactile solutions are critical. PU tactile in railway stations ensures that visually impaired passengers can safely navigate platforms, entrances, and boarding areas. At bus stops and metro stations, they provide clear guidance on safe waiting zones and crossing points.

2. Sidewalks, Pedestrian Crossings, and Traffic Signals

On city sidewalks and at pedestrian crossings, PU tactile tiles act as warning surfaces, alerting people to traffic intersections and road hazards. Near traffic signals, they indicate safe waiting areas while providing tactile cues for when to proceed. Their slip-resistant design makes them reliable even in rainy or high-traffic urban areas.

3. Shopping Malls, Airports, Corporate Parks, and Commercial Complexes

In shopping centres and airports, PU tactile tiles enhance accessibility by creating seamless navigation paths across wide concourses and waiting areas. Corporate parks and commercial complexes also use these tiles to comply with accessibility standards, while ensuring that visitors, employees, and clients move safely within high-footfall zones.

4. Healthcare Facilities, Schools, and Universities

Accessibility is a non-negotiable requirement in places such as hospitals, clinics, rehabilitation centres, schools, and universities. PU tactile tiles guide patients, students, and visitors safely through hallways, staircases, and outdoor paths. For institutions that prioritise inclusivity and compliance with disability access standards, PU tactile tiles provide a reliable, long-term flooring solution.

5. Indoor & Outdoor Applications

Unlike some materials that are suitable only for interiors, PU tactile tiles work equally well indoors and outdoors.

- Indoor: Shopping centres, airports, corporate offices, and schools.

- Outdoor: Railway platforms, sidewalks, parks, plazas, and bus stops.

Benefits of PU Tactile Tiles for Accessibility & Compliance

The primary purpose of tactile ground surface indicators (TGSI) is to improve safety and inclusivity in public and commercial spaces. PU tactile tiles go beyond being just durable flooring solutions, they are essential accessibility compliance tactile indicators that meet local and international standards.

1. Enhancing Mobility for Visually Impaired Pedestrians

For individuals with low vision or complete blindness, safe navigation depends on tactile cues they can feel with their feet or a cane. PU tactile tiles, designed with warning studs and directional bars, provide clear and reliable guidance across platforms, sidewalks, crossings, and building entrances. PU tactile tiles enhance mobility, enabling visually impaired pedestrians to navigate public spaces with greater independence and confidence.

2. Compliance with Australian Standards (AS/NZS 1428.4.1)

In Australia, accessibility is governed by AS/NZS 1428.4.1, which sets strict requirements for the installation and performance of tactile indicators. PU tactile AS/NZS 1428 compliant tiles ensure that infrastructure projects—whether government, transport, or commercial—adhere to national regulations. This not only avoids legal penalties but also demonstrates a commitment to inclusive design.

3. Meeting Global Accessibility Standards (ADA, ISO 23599)

Beyond Australia, PU tactile tiles also comply with leading international standards such as the Americans with Disabilities Act (ADA) in the United States and ISO 23599 globally. These frameworks ensure consistent accessibility across airports, railway networks, shopping complexes, and healthcare facilities worldwide. PU TGSI compliance tiles make it easier for international projects to meet regulations across multiple regions.

4. Improves Safety, Inclusivity, and Wayfinding

Safety and inclusivity are at the heart of modern urban design. PU tactile tiles:

- Improve safety by warning pedestrians of hazards like staircases, escalators, and traffic crossings.

- Promote inclusivity by ensuring everyone—regardless of ability—can access public and private spaces.

- Enhance wayfinding by guiding pedestrians through complex layouts such as airports, universities, and transport terminals.

5. Cost-Effective Installation and Maintenance

Compared to stainless steel or brass alternatives, PU tactile tiles are more affordable while still providing long-lasting performance. Their lightweight design makes installation easier and faster, reducing labour costs. In addition, their UV stability, slip resistance, and durability minimise ongoing maintenance expenses, making them one of the most cost-effective accessibility flooring solutions available.

Installation of PU Tactile Tiles

One of the biggest advantages of PU tactile tiles is how simple they are to install compared to traditional concrete or ceramic solutions. Whether you’re upgrading an existing space or designing a new accessibility pathway, this PU tactile installation guide will help ensure durability, compliance, and safety.

1. Self-Adhesive Backing vs Adhesive Installation

PU tactile tiles are available in two main installation formats:

- Self-Adhesive Tactile Tiles

- Features a built-in peel-and-stick backing.

- Ideal for fast, cost-effective projects where minimal tools are required.

- Perfect for retrofitting existing surfaces like vinyl, ceramic, and stone floors.

- Adhesive Installation (Glue-Down Method)

- Recommended for heavy traffic areas where extra bonding strength is needed.

- Requires applying industrial-grade adhesive to the underside of the tile before installation.

- Provides maximum durability for outdoor projects such as sidewalks, railway platforms, and crossings.

2. Peel-and-Stick Method Explained

The peel-and-stick self-adhesive option makes PU tactile tiles an easy install TGSI tile solution.

Steps:

- Clean the surface thoroughly to remove dust, oil, or moisture.

- Peel off the protective backing from the tile.

- Position the tile correctly based on compliance guidelines (studs for warning, bars for direction).

- Press firmly to ensure proper bonding.

- Allow adequate curing time before heavy pedestrian use.

3. Surfaces Where PU Tactile Tiles Can Be Installed

PU tactile tiles are highly versatile and can bond securely to a wide range of surfaces, including:

- Stone

- Timber

- Vinyl flooring

- Ceramic tiles

- Glass

- Metal

4. Tips for Long-Lasting Adhesion

To ensure PU tactile tiles perform reliably over time:

- Always clean and dry the surface before installation.

- Avoid installing on uneven or cracked surfaces.

- For outdoor use, prefer adhesive installation for extra durability.

- Perform routine inspections to check for edge lifting or wear.

5. Maintenance Best Practices

PU tactile tiles are designed for low-maintenance performance, but following simple practices ensures they stay effective:

- Regularly clean with mild detergent and water to maintain slip resistance.

- Avoid harsh chemicals that may degrade the polyurethane.

- Inspect tiles annually for wear and replace damaged pieces promptly.

- Ensure UV-protection is intact in outdoor applications to prevent fading.

Buying Guide: Choosing the Right PU Tactile Tiles

Selecting the right PU tactile tiles is not just about meeting compliance standards—it’s also about ensuring durability, safety, and long-term cost efficiency. With a wide variety of suppliers and materials available, making the right choice can feel overwhelming. This buying guide will help you evaluate options and make an informed decision, whether you’re sourcing locally or planning to buy PU tactile tiles online.

1. Key Factors to Consider

Before purchasing, evaluate PU tactile tiles based on these critical features:

- Durability: Ensure tiles are made from premium polyurethane that withstands heavy foot traffic and outdoor weather conditions.

- Compliance: Check that the tiles meet AS/NZS 1428.4.1 (Australia), ADA (USA), or ISO 23599 standards for accessibility.

- Slip-Resistance: Safety is non-negotiable. Look for tiles with tested slip resistance in wet and dry conditions.

- Design: Choose between warning studs and directional bars based on the intended application, while ensuring a visually contrasting colour for maximum effectiveness.

2. Supplier Checklist

When evaluating a PU tactile supplier in Australia, India, or globally, look for:

- Certifications: Compliance certificates proving adherence to international accessibility standards.

- Warranties: A strong warranty ensures confidence in product longevity.

- Customer Support: Technical guidance, installation support, and after-sales service.

- Project Experience: Established suppliers often have experience in railway stations, airports, malls, and healthcare projects, adding credibility.

3. Wholesale vs Retail Buying

- Wholesale Buying: Best for large infrastructure projects like corporate parks, public transport hubs, or smart city developments. Bulk orders often come with discounts and direct manufacturer support.

- Retail Buying: Suitable for small installations such as private offices, schools, or local council upgrades. Retail purchases may cost more per tile but are practical for limited quantities.

4. Cost Factors to Consider

When calculating project budgets, factor in:

- Price per tile (varies by supplier, material quality, and compliance certification).

- Bulk order benefits, including reduced per-unit cost.

- Installation expenses, especially if adhesive application is required.

- Maintenance savings, since PU tactile tiles have lower upkeep costs compared to concrete or ceramic alternatives.

5. Where to Buy PU Tactile Tiles

You can source PU tactile tiles through two primary channels:

- Direct Manufacturers:

- Offer wholesale pricing.

- Provide customisation options in colour, size, and design.

- Example: A tactile tiles manufacturer in India is supplying international markets with cost-effective yet compliant products.

- Online Suppliers:

- Convenient for councils, contractors, and facility managers.

- Easy to buy PU tactile tiles online in Australia, India, and other regions.

- Ideal for smaller or urgent projects requiring fast delivery.

PU Tactile Tiles in Smart Cities & Future Trends

As urban populations grow, cities are transforming into smart, inclusive ecosystems. Accessibility is no longer optional—it’s a core principle of modern urban planning. Among the many innovations, PU tactile tiles are emerging as a key tactile solution for smart cities, enhancing safety, mobility, and inclusivity while aligning with future-ready design standards.

Role in Urban Planning and Inclusive Design

Smart cities are built on people-centric design. Tactile ground surface indicators (TGSIs), especially those made from polyurethane (PU), are playing a central role in this transformation:

- Wayfinding for all: PU tactile tiles guide visually impaired pedestrians safely through stations, malls, sidewalks, and transit hubs.

- Inclusive design: By complying with global standards like AS/NZS 1428.4.1, ADA, and ISO 23599, these tiles support universal accessibility.

- Urban resilience: Unlike concrete or ceramic, PU tactiles offer durability, slip resistance, and weather tolerance, ideal for evolving city infrastructure.

Conclusion: PU Tactile Tiles as the Future of Accessibility

Accessibility is no longer a choice—it’s a necessity in every modern infrastructure project. Throughout this guide, we’ve seen how PU tactile tiles combine safety, accessibility, and durability into a single solution. From railway stations and shopping centres to smart cities and eco-friendly developments, polyurethane tactiles are reshaping the way we design inclusive public spaces.

Unlike concrete, brass, or ceramic alternatives, PU tactile indicators stand out for their flexibility, slip resistance, weather durability, and compliance with global standards such as AS/NZS 1428.4.1, ADA, and ISO 23599. They don’t just meet regulations—they enhance mobility, inclusivity, and user confidence in high-traffic environments.

Why Architects, Contractors, and Councils Should Act Now

- Architects & Urban Planners: Future-ready projects demand sustainable and compliant tactile solutions. PU tactiles align perfectly with smart city goals.

- Contractors & Builders: Easy installation methods (self-adhesive and peel-and-stick) reduce labour costs and project timelines.

- Councils & Government Bodies: Adopting PU tactile tiles ensures compliance, improves public safety, and supports accessibility mandates.

Faq

PU tactile tiles are made of polyurethane (PU), a strong yet flexible material known for its durability, slip resistance, and weather tolerance. Unlike concrete or ceramic tiles, PU tactiles are lightweight, easy to install, and long-lasting.

Yes. PU tactile tiles are designed for both indoor and outdoor applications. They are resistant to UV rays, corrosion, heavy foot traffic, and weather changes, making them suitable for sidewalks, pedestrian crossings, transport hubs, and outdoor plazas.

PU tactile tiles come with self-adhesive backing or can be installed using adhesives. The peel-and-stick method makes installation quick and cost-effective. They adhere securely to stone, timber, vinyl, ceramic, glass, and metal surfaces when installed correctly.

Yes. PU tactile tiles comply with Australian Standards AS/NZS 1428.4.1 for tactile ground surface indicators (TGSI). They also align with global accessibility codes such as the Americans with Disabilities Act (ADA) and ISO 23599.

- Warning PU Tactile Tiles: Feature raised studs to alert pedestrians of hazards, such as road crossings or platform edges.

- Directional PU Tactile Tiles: Contain strips/bars that guide pedestrians along safe, accessible routes.

- Direct manufacturers (ideal for bulk or wholesale orders)

- Specialised accessibility product suppliers in Australia, India, and globally, such as Eminent Tactiles

- What Are PU Tactile Tiles?

- Types of PU Tactile Tiles

- Why Polyurethane? (Material Advantages)

- Where Are PU Tactile Tiles Used?

- Benefits of PU Tactile Tiles for Accessibility & Compliance

- Installation of PU Tactile Tiles

- Buying Guide: Choosing the Right PU Tactile Tiles

- PU Tactile Tiles in Smart Cities & Future Trends

- Role in Urban Planning and Inclusive Design

- Integration with Smart Flooring and IoT Navigation

- Conclusion: PU Tactile Tiles as the Future of Accessibility

offer now at

Our Clients